Retransfer ID Card Printers: Advanced Technology for Superior Printing

Expert guidance. Transparent comparisons. Exceptional results.

Explore Printers

Why Choose Retransfer Printing?

Advanced Printing Process:

Images printed onto clear film, then thermally bonded onto cards.

Complete Edge-to-Edge Coverage:

No white borders or gaps.

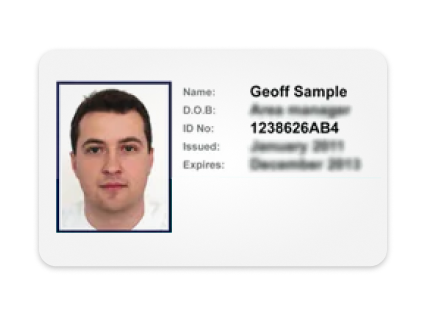

Unmatched Image Quality:

Vibrant, sharp, photo-realistic prints.

Exceptional Durability:

Permanent, scratch-resistant cards.

Versatile Material Compatibility:

PVC, PET, ABS, polycarbonate, and smart cards.

Enhanced Security:

Detailed, high-resolution prints resist counterfeiting.

Retransfer vs. Direct-to-Card

Retransfer Printing

Seaory R330/R660

- Edge-to-edge printing

- Sharp details, vibrant colors

- Durable and resistant to fading

- High-resolution print quality

- Extensive surface compatibility

Direct-to-Card (DTC)

Other brands

- 1/16th millimeter white border

- Moderate image clarity

- Easily scratched

- Moderate print quality

- Limited surface compatibility

Seaory R330 Retransfer Printer

$3,999.00

see warranty details below

Seaory R660 Retransfer Printer

$4,999.00

All R330 features, plus:

see warranty details below

Seaory vs. Fargo Printers

Seaory: Trusted Worldwide

-

Durable metal chassis withstands intensive use

-

User-friendly touchscreen minimizes training

-

Lifetime software license saves long-term costs

-

Exceptional customer ratings (average 4.9 stars)

-

Included comprehensive 3-year warranty for ultimate peace of mind

"Our Seaory printer exceeded all expectations—reliable, high-quality, and excellent support."

IT Director Verified Customer

"Super great support team. Bryon walked me through the entire setup process. This is a great printer!"

IT Officer Verified Customer

"Byron has been a great help. every time he gets on the phone with me, I feel relieved and like I learned something."

GMIT Verified Customer

"Great support! Thanks again Byron! He helped set up my printer and making sure that everything is running smoothly together with the software."

IT Director Verified Customer

Select your ideal software

Bodno Software

Bronze Edition

Included- Easy card creation

- Drag-and-Drop Editor

Bodno Software

Silver Edition

Includes Bronze features

- Excel/CSV Import

- QR Code Support

Bodno Software

Gold Edition

Includes Silver features

- Advanced Database Connectivity

- Face Cropping

- 2D Barcodes

Bodno Software

Platinum Edition

Includes Gold features

- Smart card/RFID support

- ODBC database integration

Bodno Software

Diamond Edition

Includes Platinum features

- Network licensing for 16 PCs

Choose the Right Printer — Know the License

Each printer comes with either a one-time or a lifetime software license. The type depends on the model

Lifetime License Seaory

-

Valid for the lifetime of the printer

Valid for the lifetime of the printer

-

Unlimited support & updates

Unlimited support & updates

-

No hidden fees

No hidden fees

One-Time Limited Fargo

-

Limited license duration

Limited license duration

-

Support & updates cost extra

Support & updates cost extra

-

Additional long-term expenses

Additional long-term expenses

Real Customer Reviews

Sarah Jacobs,

K-12 School Administrator

“Bodno's ID printer has completely streamlined our process. We now print all student IDs in just minutes, which has saved us so much time during registration. It’s been a game-changer for our school.”

Tom Reynolds,

Healthcare IT Director

"Switching to Bodno has made ID card production easier than ever. The system works flawlessly with our hospital's software, and the speed has made our workflow so much more efficient. Highly recommend!"

Jessica Martinez,

Nonprofit Coordinator

"Running a nonprofit means we have to be cost-conscious, but Bodno provided great value with everything included in the box. The quality and speed of printing have helped us stay on top of our security and identification needs."

Kevin McCarthy,

Police Department Supervisor

"As a law enforcement agency, having reliable and secure ID cards is essential. Bodno's printer is fast, easy to use, and has eliminated the confusion we faced with other systems. It has improved our daily operations significantly."

Seaory’s Included 3-Year Comprehensive Warranty

Every Seaory printer purchase automatically includes our industry-leading 3-year comprehensive warranty—giving you ultimate protection and peace of mind at no additional cost.

-

Free 1-Day Shipping Both Ways

Easy and fast repair process

-

Fast Repair Turnaround

Average under 3 business days

-

Full Coverage

Complete parts replacement and labor

-

Bodno Loaner Coverage

Free loaner printer provided during repairs, keeping your business operational

FAQ

Retransfer printers deliver edge-to-edge coverage, sharper detail, and longer-lasting cards. They’re ideal for organizations that need professional-grade ID cards with high durability and security.

Seaory printers include premium features like a built-in card flattener, metal chassis, touchscreen interface, and a lifetime Bodno software license—all standard. Competing models often charge extra for these.

Yes—but for good reason. Retransfer printing uses a two-step process that produces higher-resolution, scratch-resistant cards. Seaory models still print fast: 19 seconds single-sided, 38 seconds dual-sided.

Retransfer printers apply the image to a film, then bond it to the card—avoiding direct contact with embedded chips, antennas, or textured surfaces. This prevents distortion, damage, and discoloration. On solid-color cards (like red or yellow), direct-to-card printers often reveal antenna outlines or chip placement as visible blemishes. Retransfer solves that.

Retransfer printers are ideal for government agencies, healthcare systems, law enforcement, universities, and any organization that needs secure, high-quality credentials that hold up over time.

Ready to Order Your Seaory Printer?

Retransfer technology ensures your cards feature rich colors, sharp details, and vibrant images that resist fading and scratching. Perfect for professional applications, it delivers vivid, durable prints with unmatched clarity and longevity.

-

Secure Checkout

-

Fast Shipping

-

Hassle-Free Returns

Standard Blank PVC Cards

Standard Blank PVC Cards Mylar Adhesive-Backed Cards

Mylar Adhesive-Backed Cards  Proximity Cards (Nomativ)

Proximity Cards (Nomativ)  NTAG Cards

NTAG Cards  Software

Software Upgrades

Upgrades Bodno Trial

Bodno Trial Ben King

Ben King Benjamin Cohen

Benjamin Cohen Ciara Uychoco

Ciara Uychoco Eli Feig

Eli Feig Jack Richter

Jack Richter TotalCare

TotalCare Self Serve

Self Serve Printer Setup

Printer Setup License Status

License Status